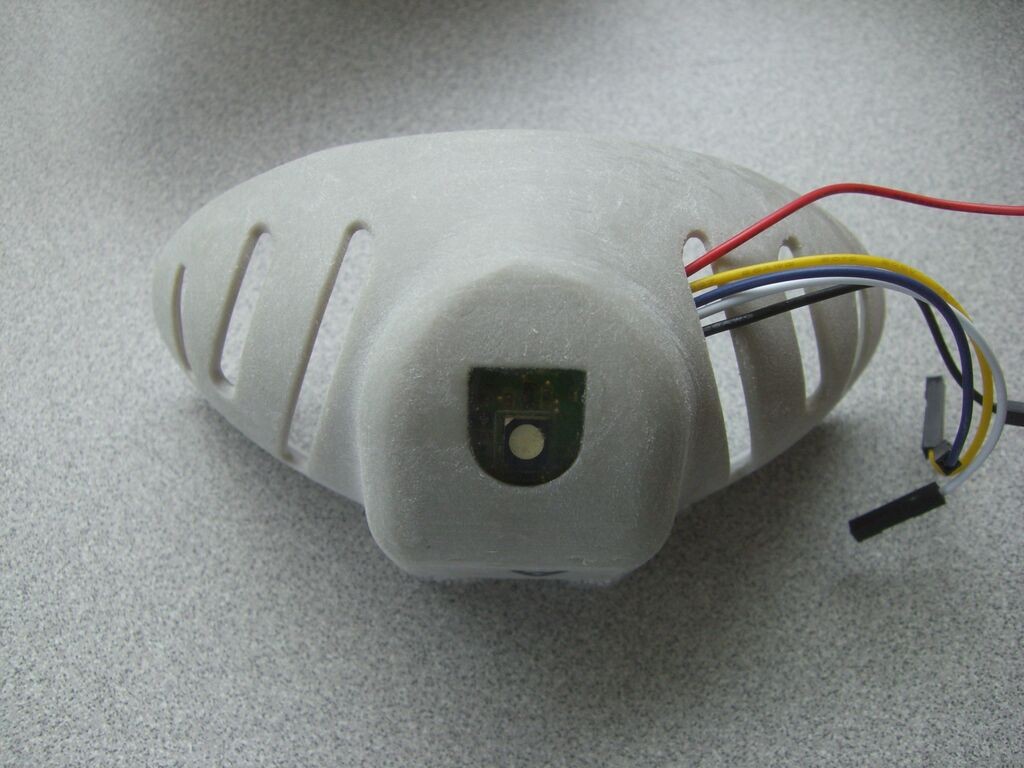

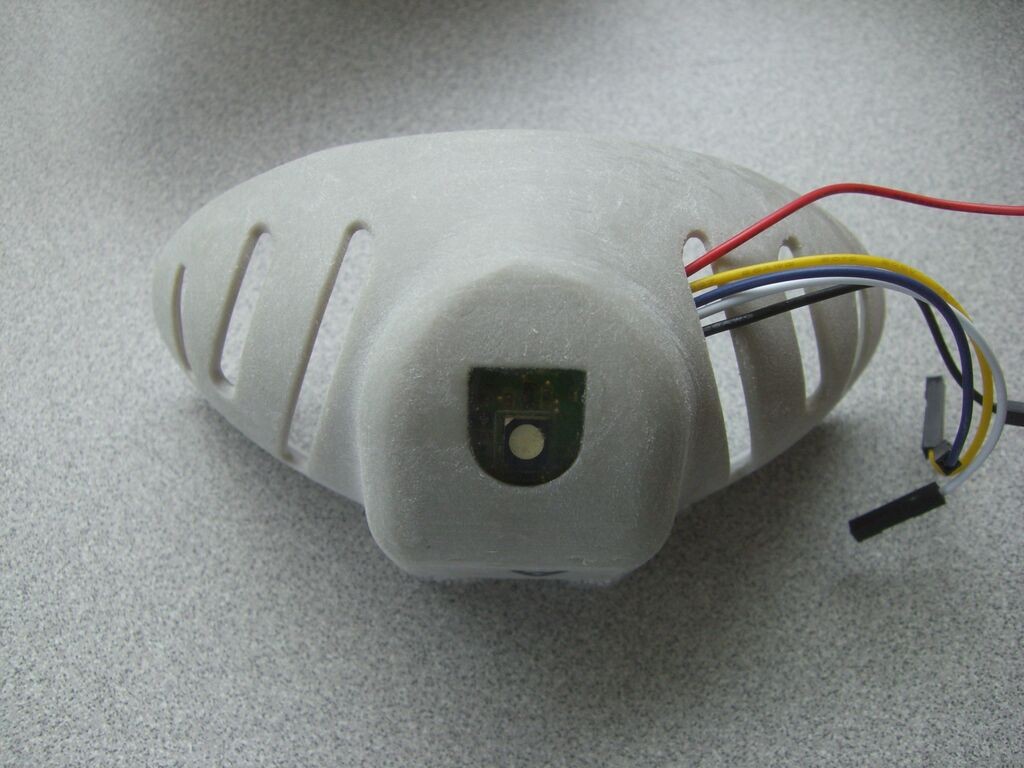

SGW Designworks was engaged by the client to develop the design for version 2.0 of this product. The design effort included parallel development of electronics, industrial design, and mechanical engineering. SGW Designworks carried the project through to manufacturing hand-off, including support of the manufacturer during tooling production.

The project involved many design review points, at which we helped the client make critical functionality / cost balancing decisions. The shape development process was iterative, and we leveraged SLS, SLA, and FDM 3D printing technologies for very very fast design iteration cycles.