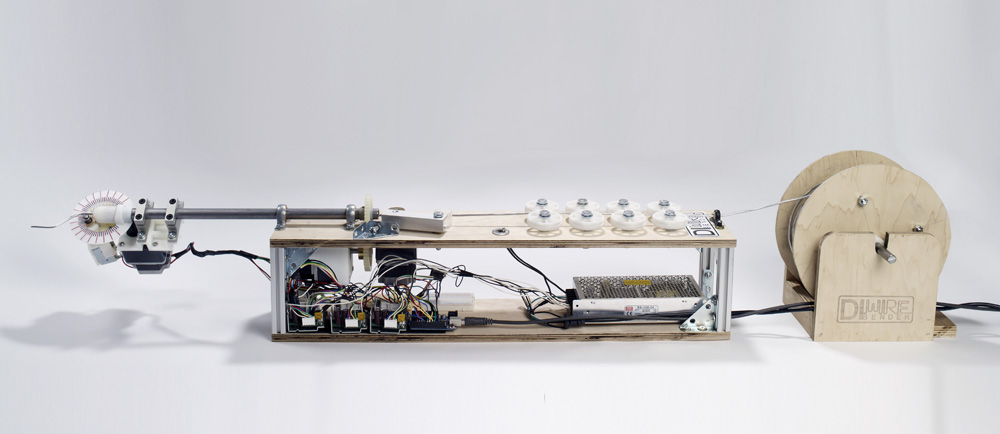

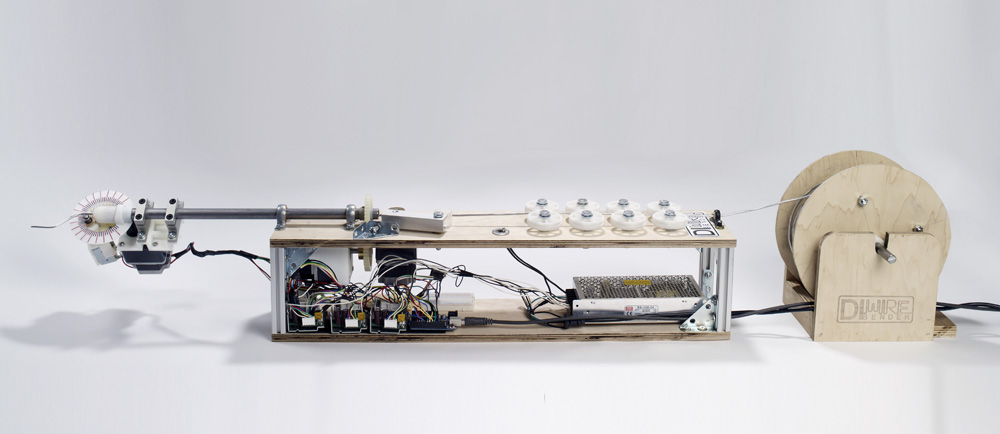

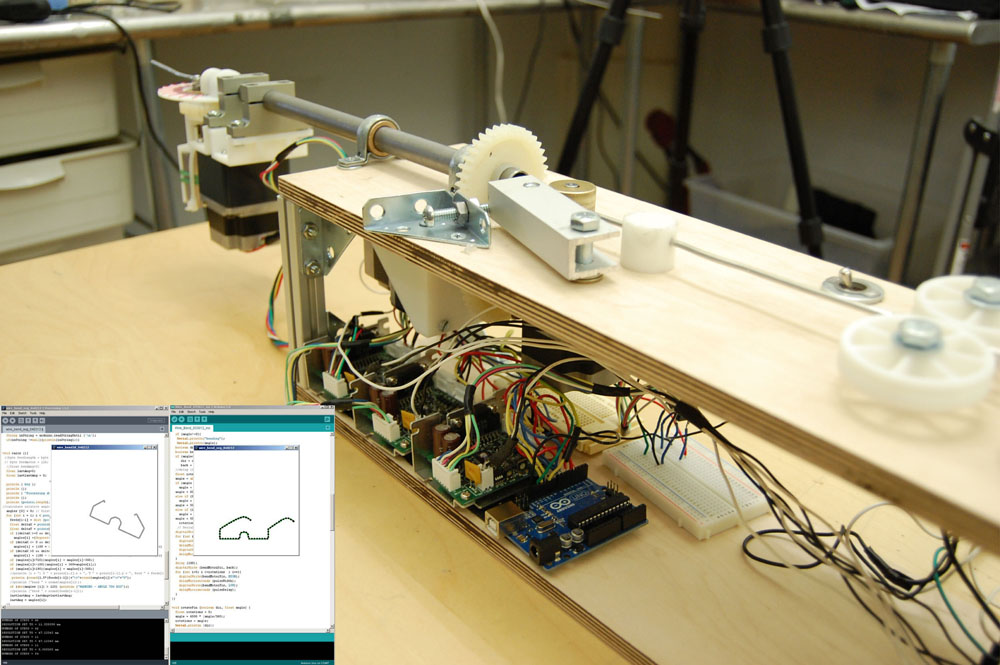

The DIWire Bender is the first desktop CNC wire bender. A new archetype for desktop manufacturing and rapid prototyping, the DIWire transforms drawn curves into bent wire that can be assembled to make just about anything.

To date, desktop manufacturing has focused on 3D printers outputting plastic volumes and laser cutters cutting 2D planes. However, nothing exists that convert lines into bent rod, wire or tubular forms quickly, accurately, and repeatably.

The DIWire can bend various metals and plastics, allowing for output to be used as the final product. Additionally, the build volume is limited only by the length of the wire. By being transportable, accessible and affordable, the DIWire fills the market gap between time-consuming hand-bending and large scale, mass production CNC wire bending, which is too expensive for custom, short-run productions. This changes the dynamics of local, mass customized, prototype and just-in-time manufacturing.

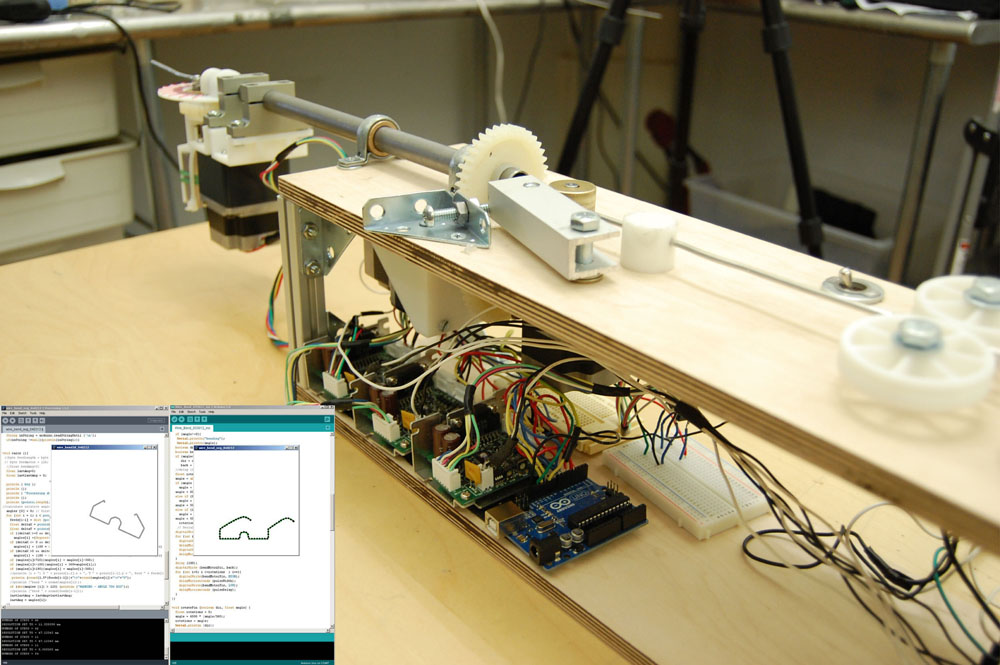

Our focus on the entire user experience, from the software interface, to the machine design, to accessories needed for assisting assembly, provides seamless workflow. Our software doesn't require specialty skills, and was designed with the education sector in mind. We hope to encourage creativity in kids and adults in science, technology, engineering, art and math, by bringing craftsmanship and accessibility to digital fabrication.

The DIWire is currently in beta testing at businesses and universities in the NYC-area. Our community has responded positively to the DIWire’s potential, telling us they want to make antennas, jewelry, architecture models, design prototypes, art, furniture, small crafts, surgical implants, orthodonture, lighting, stage sets, puppetry, robotics, short run production, signage and the list goes on.