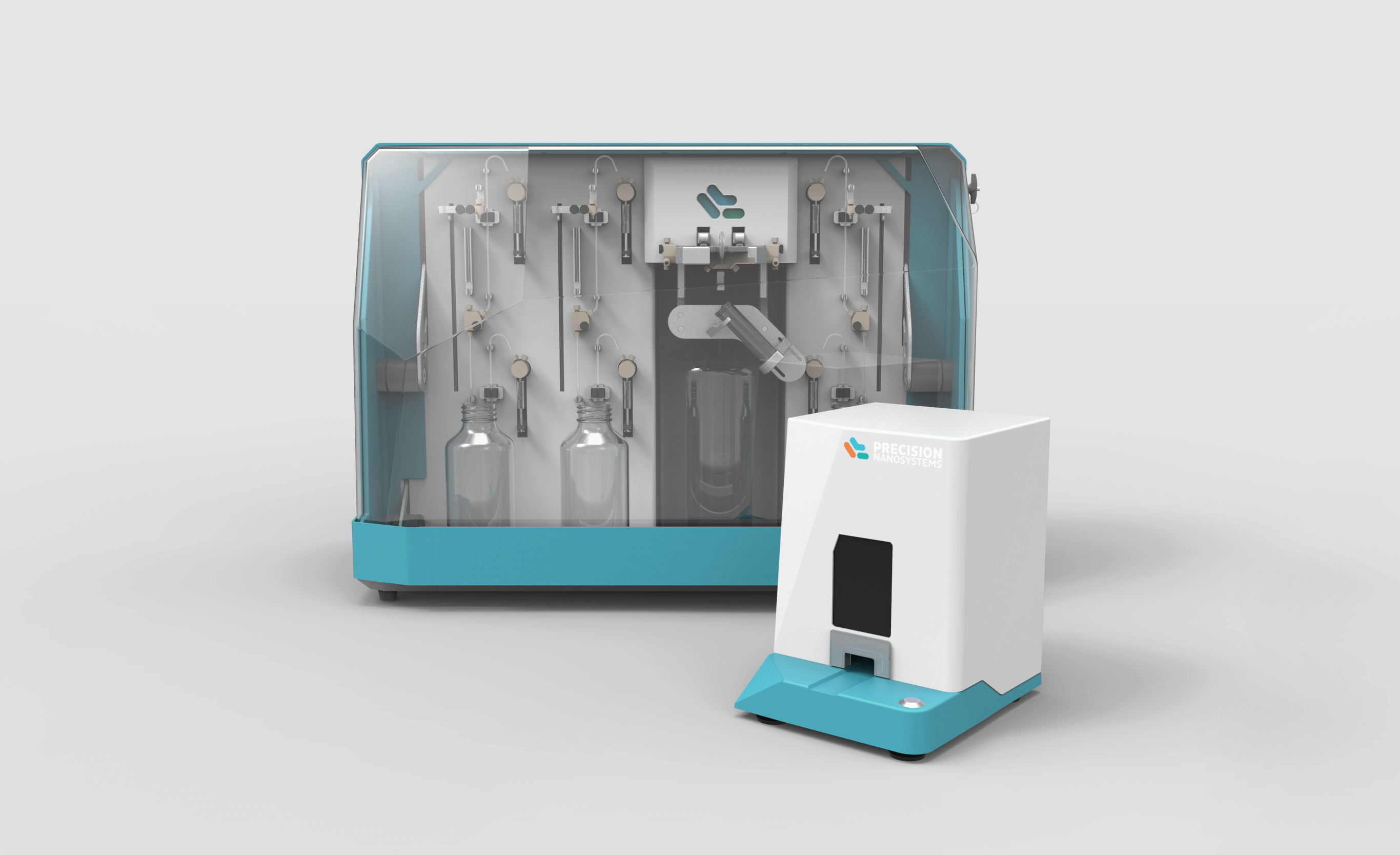

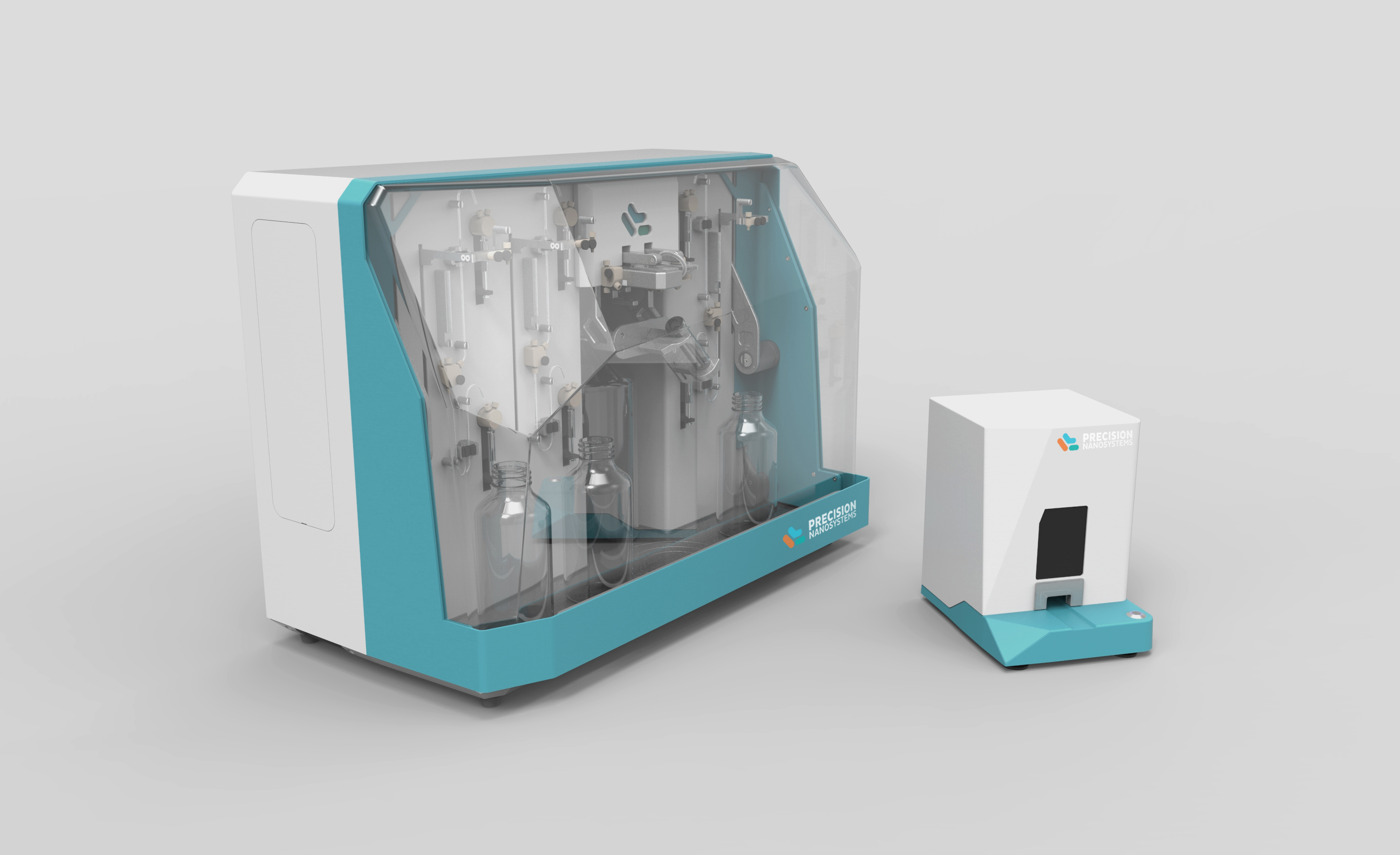

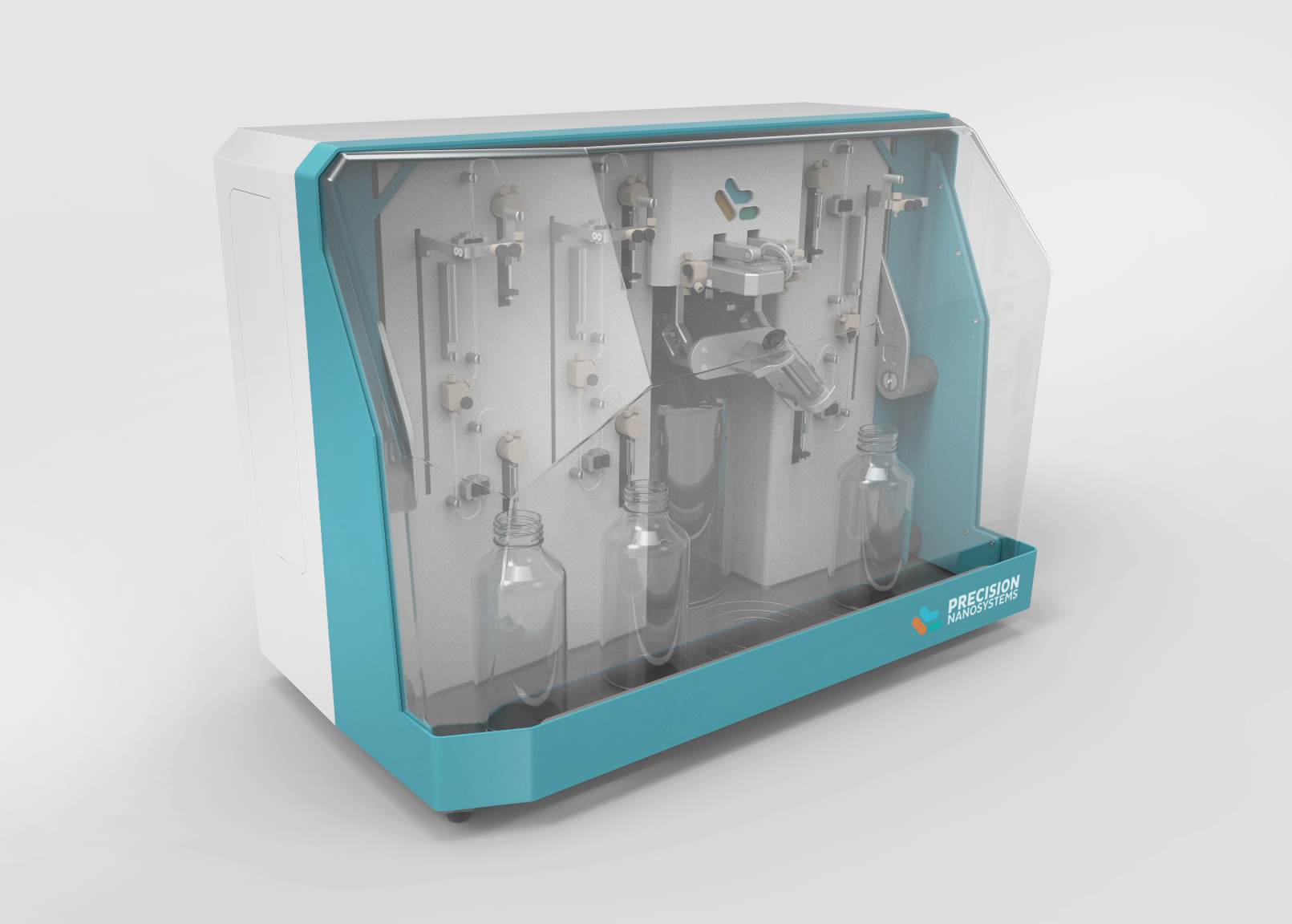

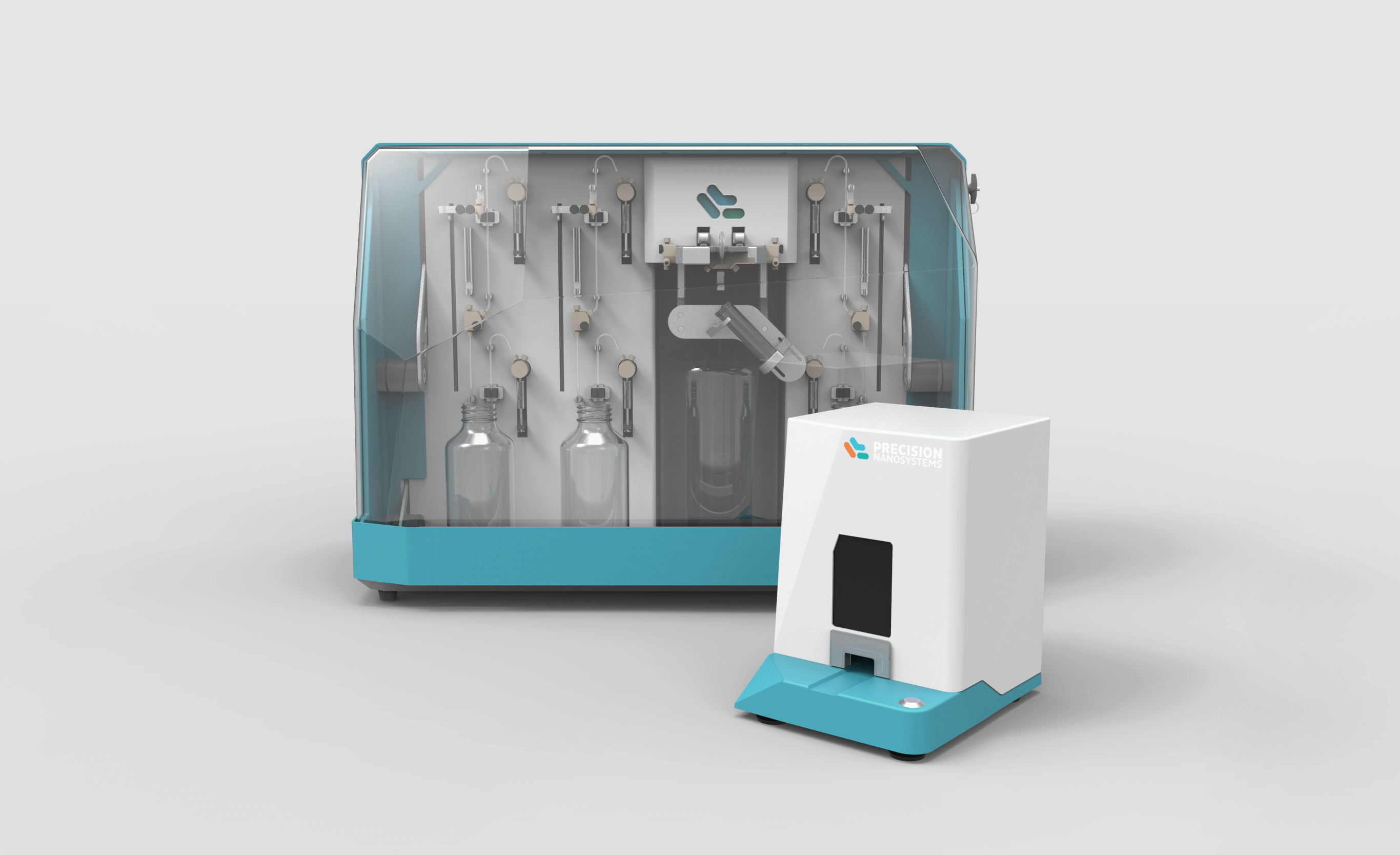

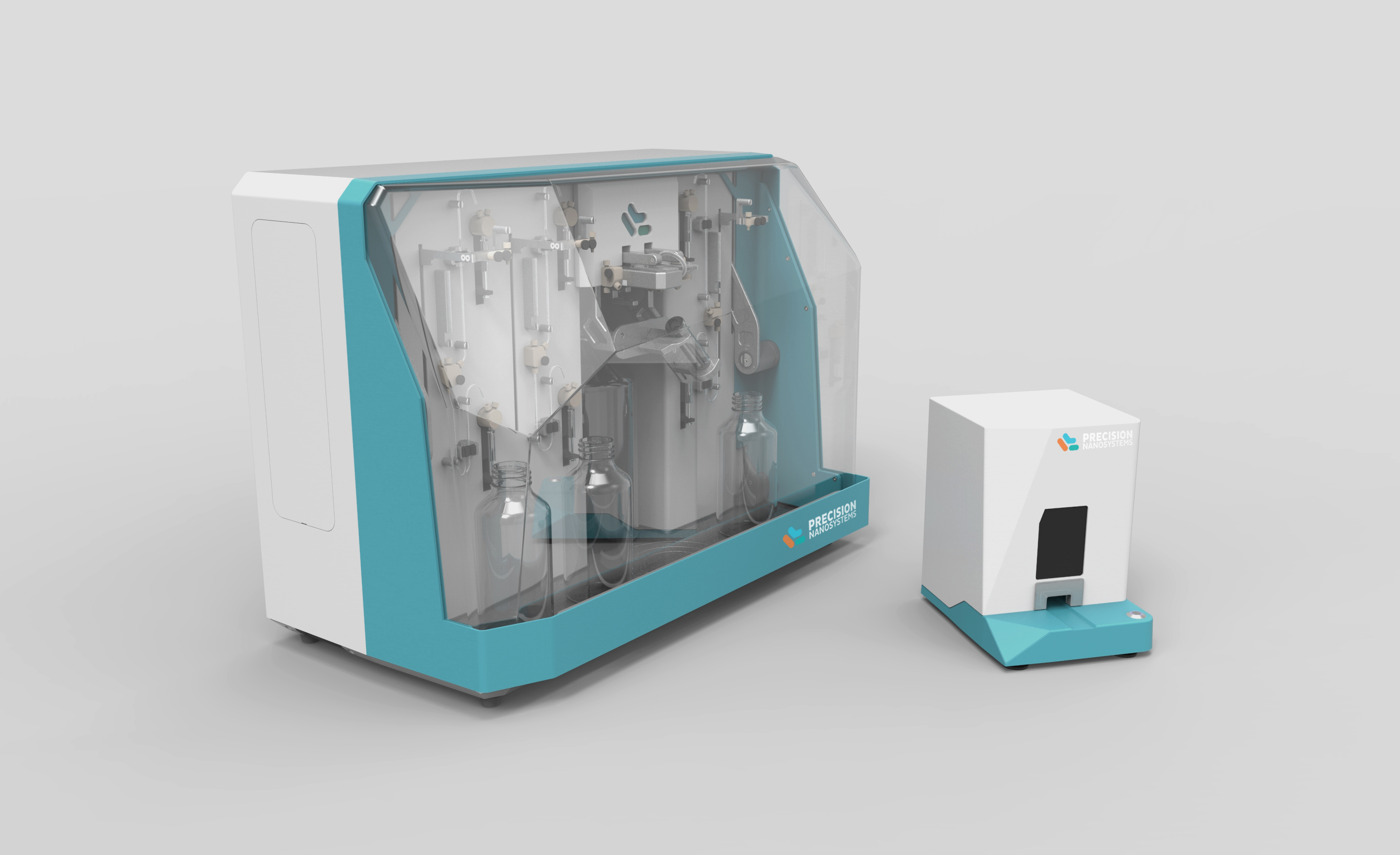

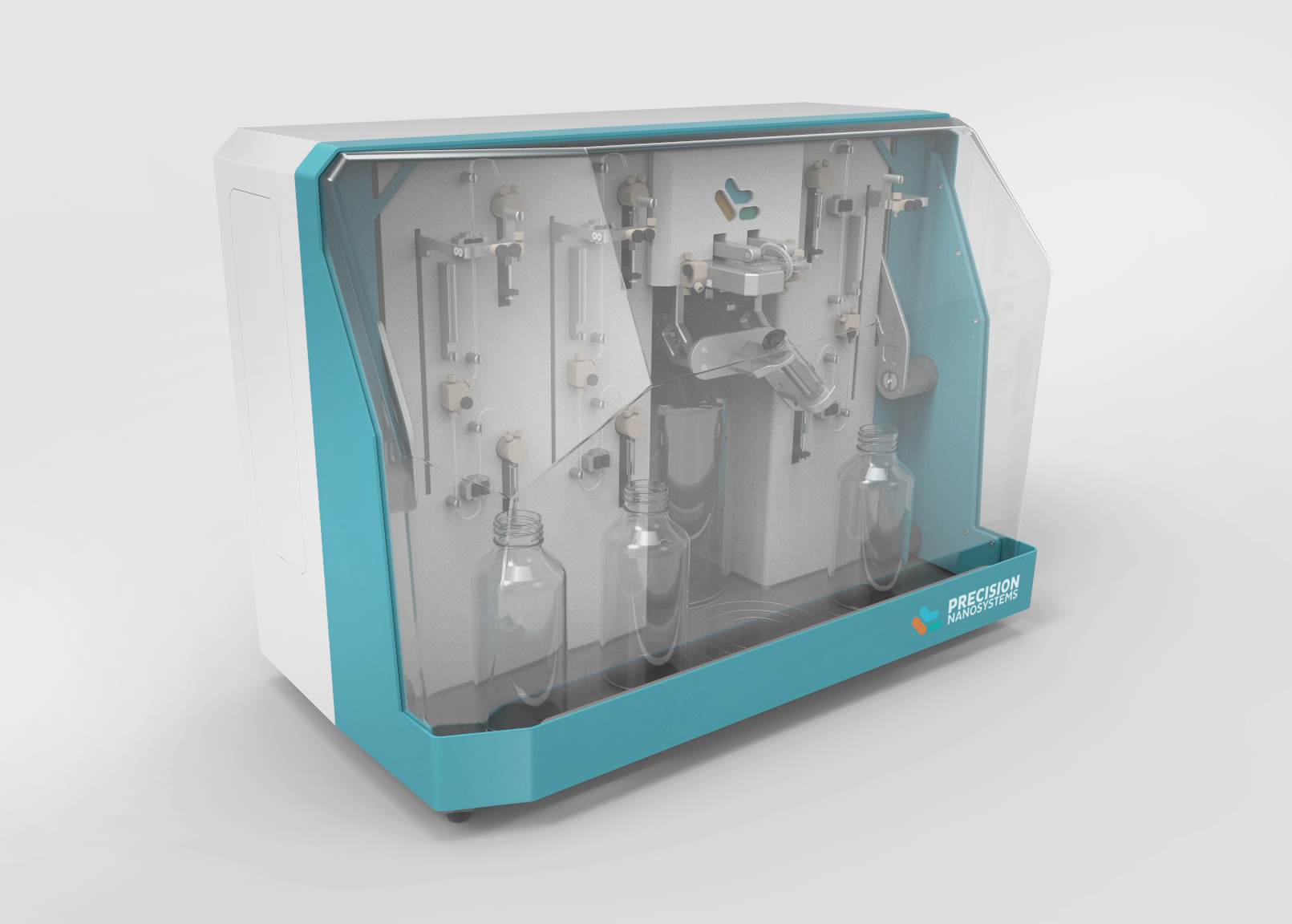

Precision NanoSystems, Inc. is revolutionizing nano medicine by producing proprietary equipment to quickly and cost-effectively enable nano-medicine to be cell-specifically delivered to targeted parts of the body for research, diagnostic imaging, diagnosis, and disease treatment. Precision NanoSystems partnered with Anvil Studios to create Industrial Design solutions for two of their machines; the large bench-top Blaze and the small single-shot Spark.

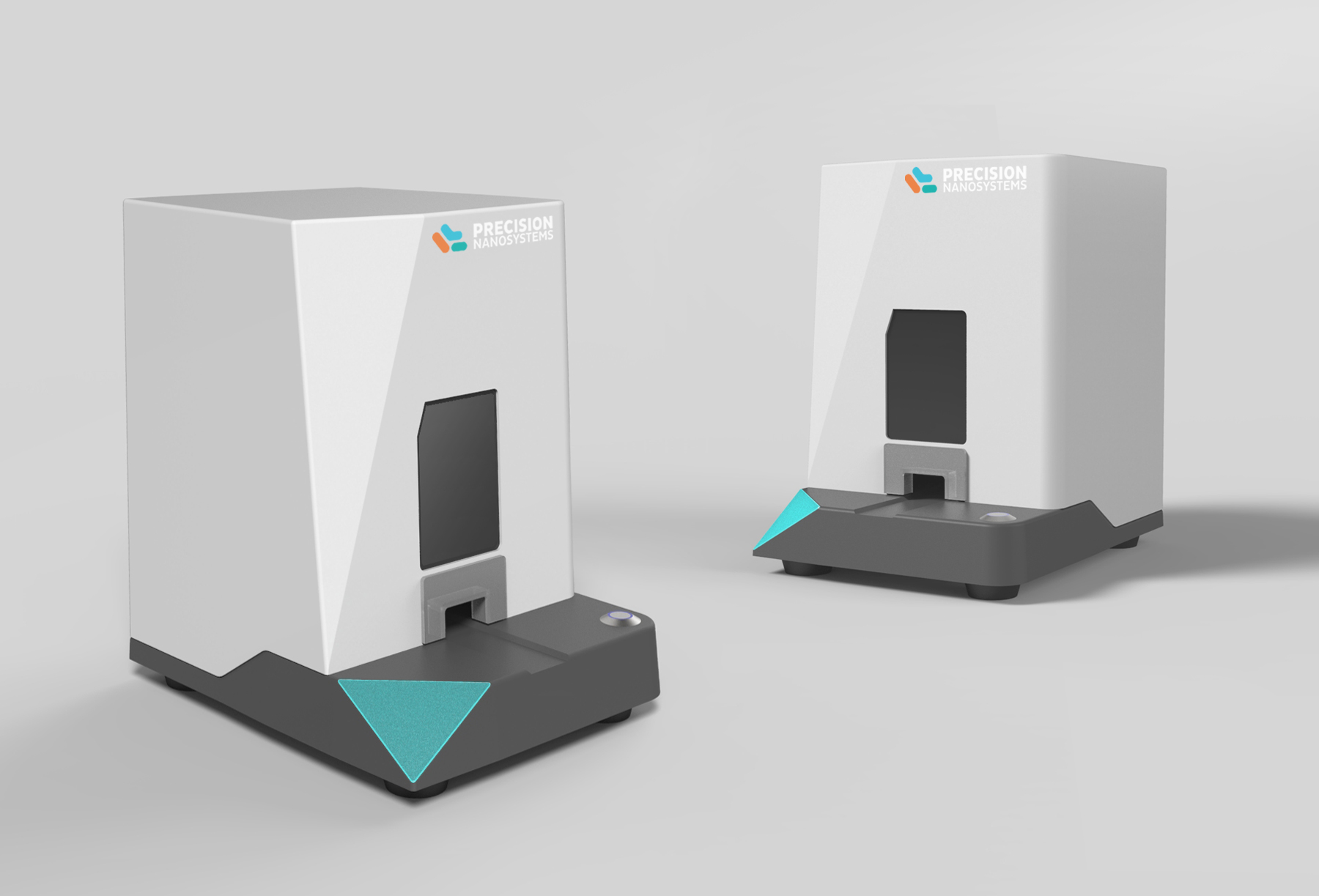

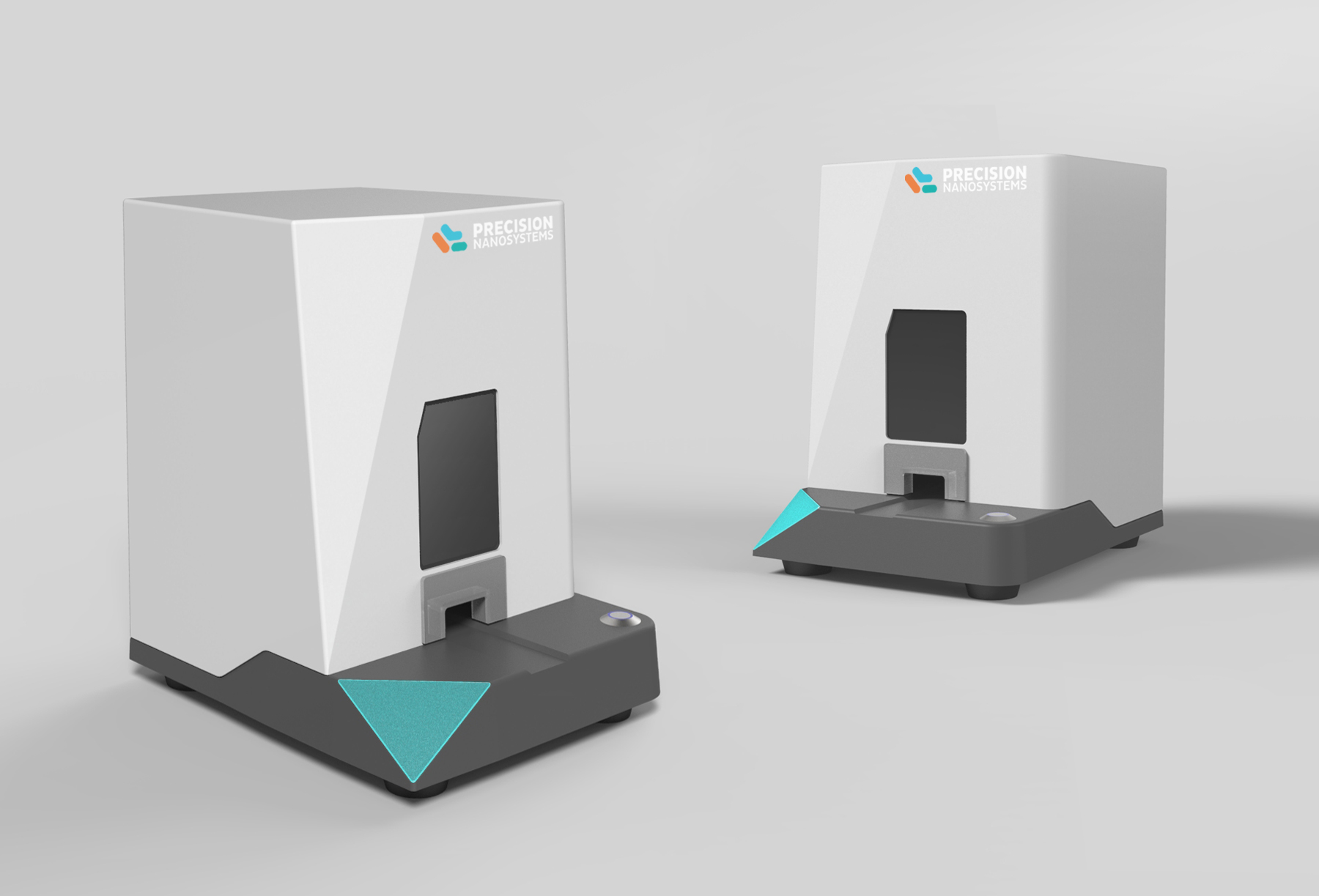

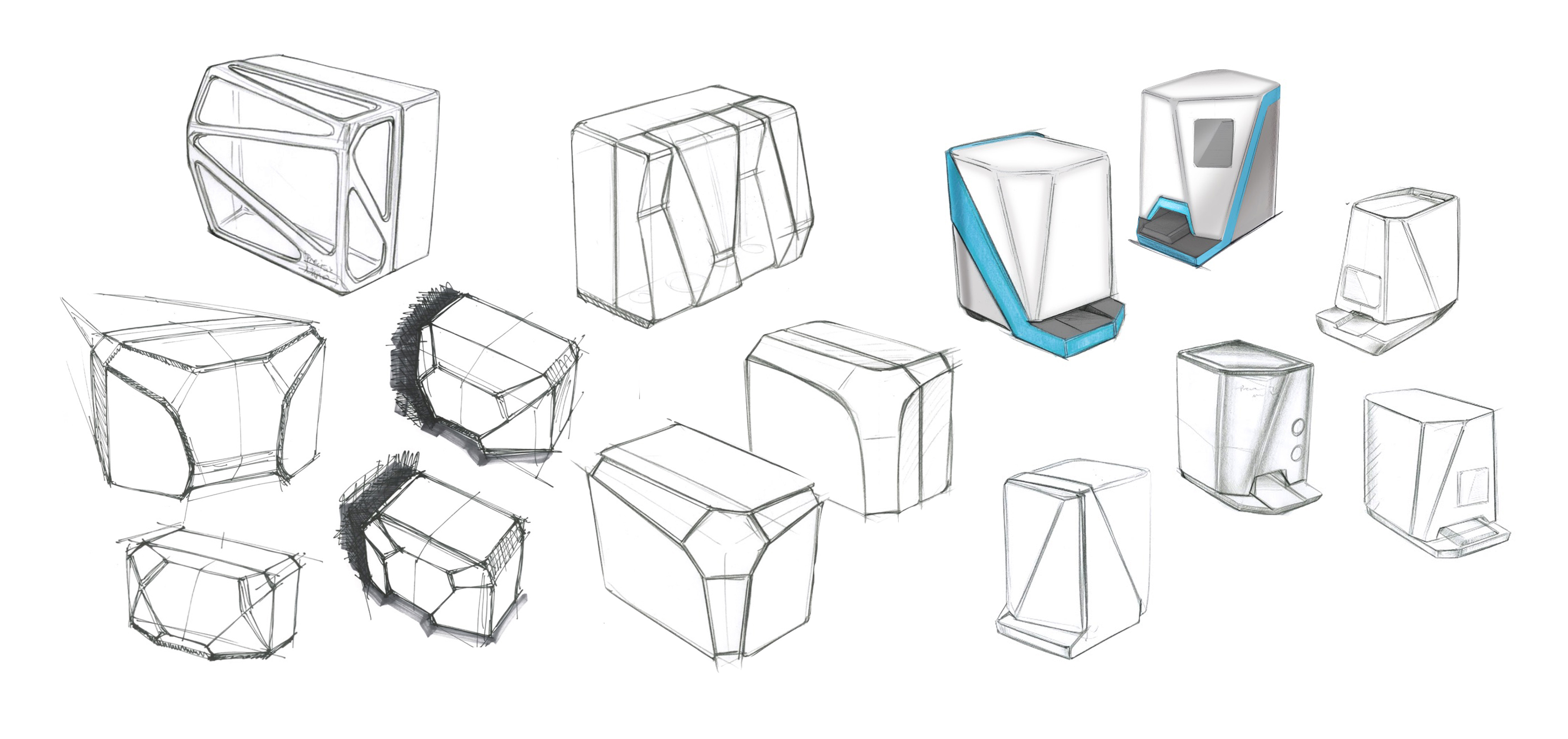

Precision NanoSystems wanted both designs to be distinctive and stand out amongst other Life Science equipment. Both products are produced in relatively low quantities, so sheetmetal enclosures were the optimal method of fabrication. The larger Blaze system has a large, clear polycarbonate front cover to allow users to easily see the mixing process. The smaller Spark unit’s main usage is in a biosafety cabinet, requiring its design to be as minimal as possible, yet still relate to the larger Blaze housing design.

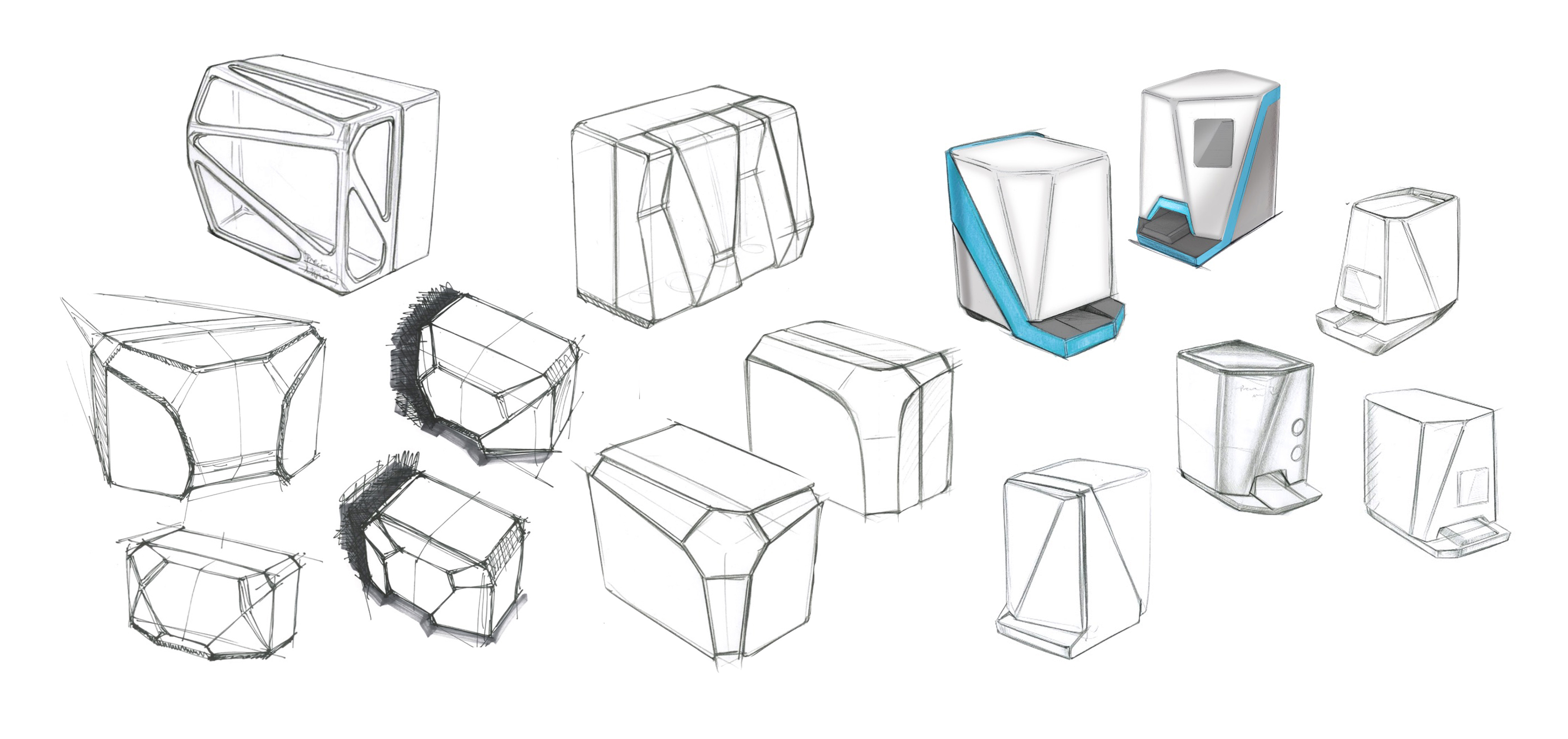

The selected design language is a dynamic, faceted form. The asymmetric application of the faceted geometries are intentionally designed to highlight the main user interaction zone on the larger Blaze system. A single asymmetric chop to the front corner face of the smaller Spark unit provides a strong visual tie to the larger system, while being as minimal as possible. The faceted form provides clean, planar bends that are easily achievable via both sheetmetal and polycarbonate bending methods.