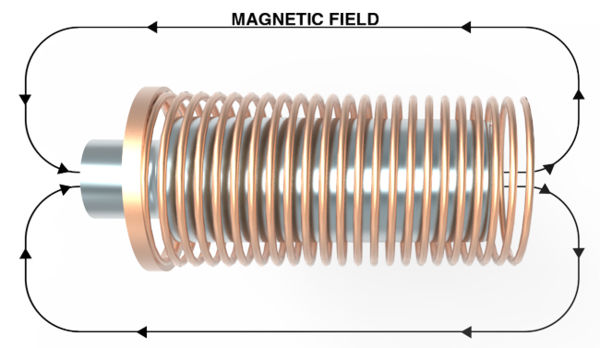

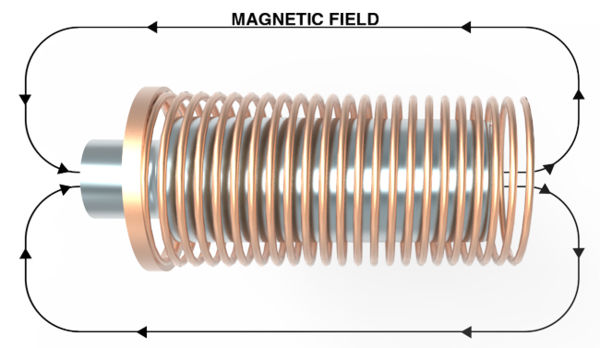

Induction is a “non-contact” heating process. By applying a high-frequency alternating current to an induction coil, a time-varying magnetic field is generated. The material to be heated, something we call a susceptor, is placed inside the magnetic field, without touching the coil. The alternating electromagnetic field induces ‘eddy currents’ in the susceptor, which then heat the susceptor. Our susceptor is made of a ferrous metal. Ferrous metals are heated by induction more easily than other materials. That is because, in addition to the ‘eddy currents’ described above, another heating mechanism occurs. The material’s iron crystals are magnetized and demagnetized over and over by the alternating magnetic field. This causes the magnetic domains to flip rapidly back and forth, leading to ‘hysteresis losses,’ which result in heat.